¶ Hardware AUV8 Overview

- The front part has both cameras, the hydrophones board and the ethernet switch.

- The back part has the backplane power and the ESC manager.

- The middle part is separated in 3. The bottom has the USB hub and IMU. The middle has all the cables and the RS485 adaptor board. Finally, the top has the IO board close to the underwater connectors.

The 2 last parts that are left and right of the middle can be switched around without any issues.

- At the left, there is the DVL and a 16000mAh batteries from MaxAmps.

- At the right, there is the PC and a 16000 mAh batteries from MaxAmps.

¶ Microcontroller

With the new submarine, we decided to change the microcontroller for our custom boards. We used to have an LPC1769 that works well but had a lot of limitations. There were a few technical caracteristics and the motivation for change. Our choice has stopped on the STM32F413VG. Another 100 pins microcontroller that has all the best features of the LPC and much more. Here are a list of the basic caracteristics of the STM32 :

- Lower price

- Faster overall speed

- Added functionalities

- Separate ADC

- Amount of timers

- Supply voltage

The STM32 microcontroller family has others benefits for our team. There is a really good online support and a application called STM32CubeMX that help us in the design of our boards. We did not use it to generate our code, just for an approbation of the pinout.

¶ Software

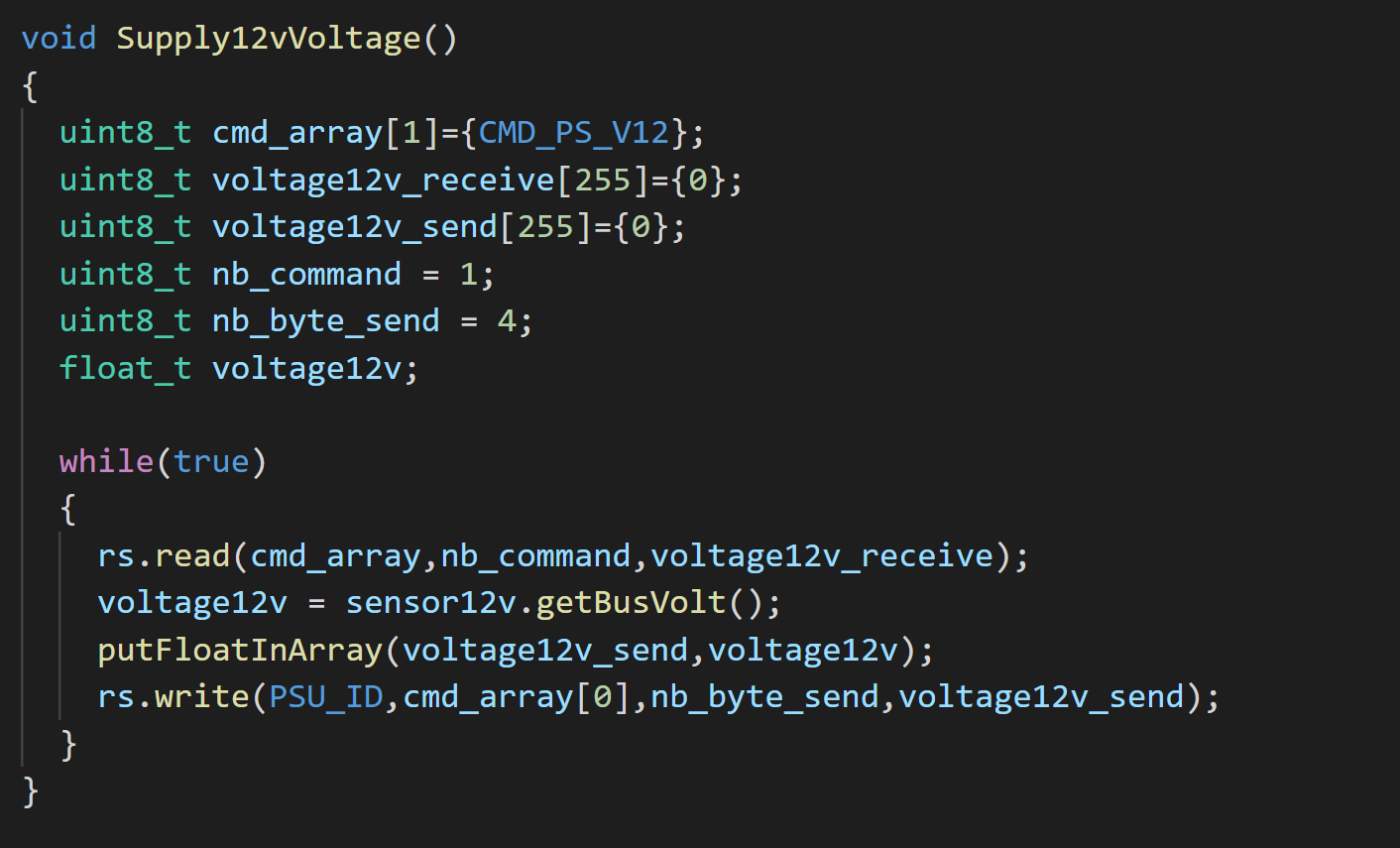

With the MBED library, we decided to integrate the RTOS(real time operating system) functionality. In our software, we have multiple threads on a microcontroller that are waiting for an RS485 command before doing the rest of the program. All the threads are declared in the main and attached to a function. The priority of all the thread have to be Above Normal or higher(see documentation of MBED RTOS for more information).

¶ DCDC Converters

We decided to use DCDC converters as much as possible on the boards for AUV8. We get a better efficiency and reduce the current draw from the batteries.

¶ Power Consumption

Our second solution to reduce the power consumption was to reduce the number of LEDs. This is exceptionnaly visible on the power supplys. The AUV7 power supplys consume approximately 0.18 amps per boards just being plugged in. With removing all the less usefull LEDs from the boards, we achieve a consumption of 0.09 amps (to verify).

¶ Communication

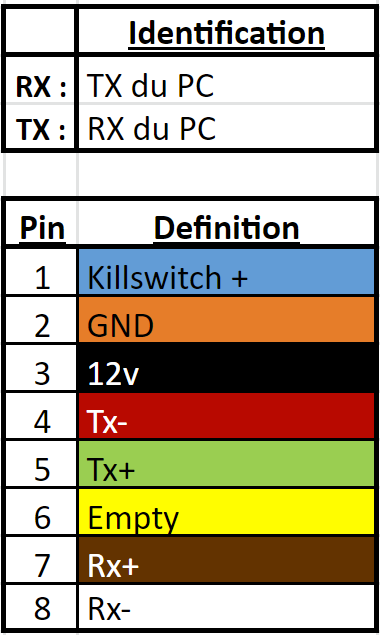

With the new submarine, we changed the cables to ethernet flat cables. They are available everywhere and the length can be custom made to suit our needs. As we designed the new AUV, we made sure this time that all the connectors had the same pinout. We have standardised the communication connectors. We have to connectors, one vertical and one right angle.

Here is the pinout description :

Ground and 12V are only used for the killswitch board.

¶ Standard Connectors

Here is the list of connectors :

- JTAG

- 12V connectors

- ESC power connectors

- USB C

¶ Board Size

¶ Compatibility with AUV7 Software

Some tweaks have been made to adapt the new microcontroller to the AUV7 software. The UART communication of the STM32 needs a little more delay to work with the RS485 bus. This could also be an issue with the MBED library.

By : Francis Alonzo

Date : 2020-01-20